After several stages of unarmed warfare, cold weapon warfare, hot weapon warfare and mechanized warfare, human war has entered information-based high-tech warfare. War is extremely cruel, but it is a rare catalyst for the development of science and technology. Today, many familiar science and technology originally came from military technology. With the end of the war, the phenomenon of military technology to civilian technology is very common. For example, electronic computers, voice translation to text technology, GPS positioning, anti-aircraft guns for artificial rainfall, launch vehicles, nuclear power plants and so on are typical military to civilian technologies.

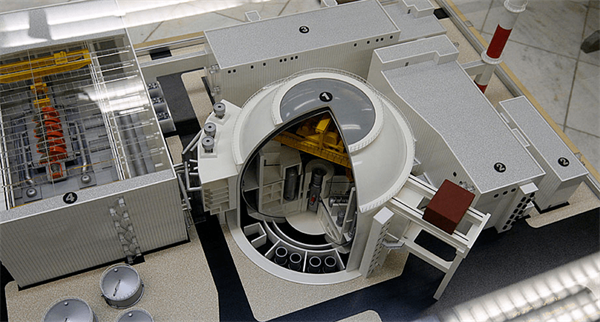

Since the first nuclear reactor was built in the United States in 1942, the nuclear industry has developed for nearly 80 years. During this period, the development focus of the nuclear industry shifted from nuclear weapons to nuclear energy applications, and the materials used in the nuclear industry were constantly updated. Advanced ceramic materials also received attention and were effectively used in various aspects such as nuclear reactor raw materials, components and nuclear waste treatment.

This paper gives a simple example of the application of advanced ceramic materials in nuclear energy industry:

1 absorber rod absorber (B4C)

In order to keep the rate of fission reaction at a predetermined level, control rods and safety rods (collectively referred to as absorption rods) are required to adjust the reaction rate, in which control rods are used to compensate for fuel consumption and adjust the reaction rate, and safety rods are used to stop the reaction quickly. The current absorber is widely used in light water reactor, heavy water reactor, high temperature cold gas reactor and fast neutron reactor. The absorber used is mainly boron carbide powder or boron carbide pellets.

Extension of relevant data of boron based ceramic materials:

The research results show that boron based ceramic materials have good neutron absorption performance. At the same time, some boron based ceramic materials such as boron carbide, zirconium boride, boron nitride and borosilicate have good performance in high temperature, high pressure and corrosion resistance. Therefore, these boron based ceramic materials are widely used in cooling system, control rod, reflector, shielding layer system and fields related to nuclear reactor, And become the main component of key materials in the field of nuclear energy.

Application of boron based ceramic materials in nuclear power equipment:

(1) Application in core elements: in the core elements of nuclear power reactors in the United States, a part of boron carbide is compounded with boron containing glass, and a coating layer is prepared outside the core elements to achieve the effect of water and hydrogen prevention.

In the 10MW high temperature gas cooled reactor htgr-10 independently researched and designed by Tsinghua University, the carbon brick made of boron carbide and carbon materials surrounds the reflector around the reactor core, which not only achieves the effect of heat insulation, but also reduces the neutron flux outside the reactor shell.

(2) Application in cooling system: the coolant of one of the important reactor systems needs boron containing materials to control the reaction. In the AP1000 reactor, the United States has applied the chemical compensator of boric acid in the coolant to control the long-term reaction change and average the capacity loss and fuel distribution. At the same time, B10 boric acid is also used as a soluble neutron absorber for control rods. In the gravity boron injection system of 200MW nuclear heating reactor in China, 8% sodium pentaborate solution is used as coolant to improve the progressiveness, safety and economy of the reactor.

(3) Application in control system: in the control system of 300WM pebble bed gas cooled fast reactor, boron carbide is used as neutron absorbing material to coat the periphery of reflector material. In sodium cooled fast reactor and lead cooled fast reactor, boron carbide is used in control rod elements to control the operation of the reactor.

(4) Application in other parts of the reactor: some reactors use metal materials as structural materials. In order to reduce the neutron radiation received by these materials, some boron based ceramic materials also need to be used as neutron absorbing materials or shielding materials to reduce the amount of neutron radiation.

2 nuclear reactor moderator (BeO)

The fission reaction in nuclear fission reactor is caused by bombardment of 235U (uranium 235). In light water reactor, heavy water reactor and high temperature cold gas reactor, slow neutrons are more likely to cause 235U fission than fast neutrons produced by neutron fission. Therefore, moderators, which can slow down the neutron speed, are needed in these reactors. At present, the commonly used moderators in the world include water, graphite, beryllium, beryllium oxide, etc., among which beryllium oxide as ceramic material is considered as a moderator in the future.

3 ceramic nuclear fuel (UO2)

Fission reactor fuel can be divided into metal fuel element, dispersion fuel element and ceramic fuel element. Ceramic fuel element is various types of ceramic pellets or spheres, and the main chemical composition is uranium dioxide. Because different reactors have different requirements for fuel performance, ceramic fuel elements with different chemical compositions and specifications will be derived. At present, UO2 ceramic pellets with or without other additives, MOX fuel pellets with other radioactive metal oxides and coated fuel particles are mainly used in each reactor.

4 SiC ceramic matrix composite cladding material for reactor

The cladding material of nuclear fuel element is an important barrier for reactor safety. With the development of nuclear power reactor towards high burnup, long fuel cycle life and high safety, the traditional Zr alloy cladding material can not meet the stringent requirements of fuel elements of the fourth generation nuclear power system in the future because of its uranium burnup limit (62 MW • D / kg), high temperature corrosion, hydrogen embrittlement, creep, irradiation growth, core / shell reaction and other defects. Because of its smaller neutron absorption cross section, low decay heat, high melting point and excellent irradiation dimensional stability, SiC based ceramic matrix composites have become the research hotspot of the new generation of cladding materials.

5 first wall structural material (SiCf / SiC)

The structural material of the first wall shall have certain resistance to neutron radiation damage. The application of ceramic materials in the first wall structural materials mainly refers to the silicon carbide matrix composites (SiCf / SiC) reinforced by silicon carbide fibers. SiCf / SiC has good corrosion and swelling resistance. As the first wall structural material, it still has high enough strength at high temperature, and can operate at high temperature of 800 ℃, allowing the coolant to reach high temperature, so as to improve the thermal efficiency of the energy system; SiC itself is a low neutron activated material with low induced radioactivity to neutron radiation. As the first wall, it is easy to maintain and carry out radioactive treatment.

Conclusion

The above examples are some ceramic materials that can be used in the nuclear industry. These ceramic materials still have a lot of research work to follow up, and their performance can be improved according to the actual application to meet the growing needs of the nuclear industry.

Technological innovation

Honesty is the foundation

Contact Number: +86-15698999555 |

Address: NO.6 ,SHENGHUA STREET,TAIHE DISTRICT, JINZHOU CITY, LIAONING PROVINCE, CHINA. |