01 molybdenum disilicide material

The crystal of molybdenum disilicide (MoSi2) has a tetragonal structure. It is an intermediate phase with the highest silicon content in the Mo Si binary alloy system. It is a Dalton intermetallic compound with fixed composition, gray and metallic luster. It has good conductivity and thermal conductivity, excellent mechanical properties and high-temperature oxidation resistance. It can be used as heating element, and its performance is better than that of silicon carbide. Its early application was as a coating protective material for high temperature and corrosion resistance on the surface of metal matrix. It was first applied to the coating of gas turbine parts, jet engine combustion chamber and missile combustion chamber. Nowadays, the main industrial application of molybdenum disilicide material is in the production of high-temperature heating elements and thermocouple protection tubes.

02 Characteristics of molybdenum disilicide material

① Crystallographic properties: it belongs to tetragonal crystal structure with a density of 5.9-6.3g/cm. Pure molybdenum disilicide has no phase transition before reaching the melting point and has good thermal stability. Within the upper limit of its effective temperature range, the rise and fall of temperature will not be damaged by the change of crystallographic properties.

② Thermodynamic properties: the melting point is up to 2030 ℃, the thermal conductivity is high (close to SiO) and the coefficient of thermal expansion is small. These characteristics are the necessary conditions for making high-temperature heating elements or thermocouple protection tubes, and are conducive to increasing the thermal shock resistance of their products.

③ Electromagnetic property: low resistivity (2) × 10-5 Ω • cm), high electrical rate, belonging to good conductor. This material is an excellent material for manufacturing heating elements, thermocouple thermal electrodes and temperature measurement protection tubes (pay attention to insulation when making thermocouple protection tubes).

④ Mechanical properties: the tensile strength and bending strength are not lower than that of general metal materials and some oxide materials (such as Al2O3), and the hardness and compressive strength are higher than that of metals. Compared with metal, the biggest disadvantage is poor impact toughness, so it belongs to brittle materials like general ceramic products. Therefore, in the actual production process, a small amount of metal binder is added without affecting its high-temperature oxidation resistance to make cermet.

⑤ Chemical properties: the chemical state is acidic. It is insoluble with most acids and bases at room temperature. Except oxide ceramics, MoSi2 has the highest antioxidant stability among all refractory compounds. Since the solubility of silicon in molybdenum is about 1% (1800 ℃), the oxidation stability temperature of MoSi2 is below 1700 ℃.

Molybdenum disilicide itself is not resistant to high-temperature oxidation, but forms a thin and dense silica glassy protective layer on its surface at 1300 ~ 1600 ℃ to inhibit further oxidation. MoSi2 is not only stable in oxidizing medium, but also can be used to quite high temperature in reducing, neutral, inert and some strong corrosive atmosphere. For example, in N2, CO2, SO2 and other media, the maximum service temperature can reach 1600 ℃.

03 preparation of molybdenum disilicide

Molybdenum disilicide can be obtained by direct reaction synthesis of Mo powder and Si powder. Or synthesized by the oxide reduction reaction of mo.

Molybdenum disilicide can be produced by cold pressing sintering or hot pressing. If molding is used, batter, starch and glycerol can be used as binder. When forming by extrusion, 2% ~ 4% dextrin is added as binder. MoSi2 products are fired at 1500 ~ 1900 ℃. If a small amount of SiO2 is added to molybdenum disilicide powder, a protective film will be formed on the surface of molybdenum disilicide products due to the melting of SiO2 at high temperature, which will increase the working temperature of molybdenum disilicide to 1710 ~ 1780 ℃. The mechanical properties of cold pressed sintered products are poor. During hot pressing, the temperature is 1550 ~ 1750 ℃, and the pressure is 9.8 ~ 78.5mpa. Molybdenum disilicide products with different properties can be obtained by hot pressing the mixture of molybdenum disilicide and alumina.

04 application of molybdenum disilicide

At present, the silicide product with the largest industrial production and the most widely used is molybdenum disilicide. Its main products are high-temperature heating elements and thermocouple protection tubes.

① Applied to electric heating elements:

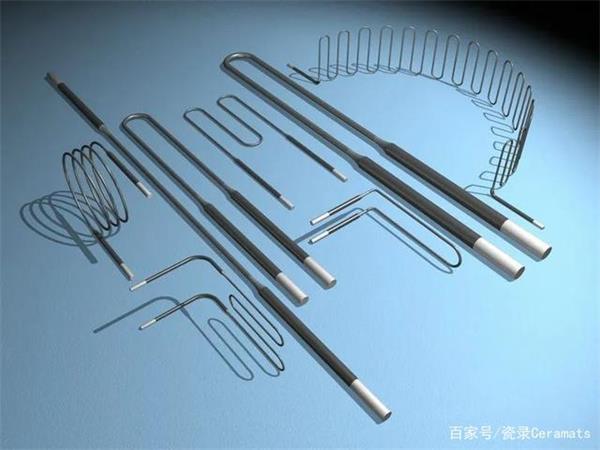

Although molybdenum disilicide heating element can be used to 1700 ℃ for a long time in oxidizing atmosphere, the furnace temperature of box resistance furnace and industrial tunnel kiln assembled with the heating element is generally only about 1600 ℃ due to heat dissipation and other factors. Molybdenum disilicide rod "U" heating element resistance furnace is widely used. At present, it still ranks first in this kind of material heating element.

Figure 1 Via network of molybdenum disilicide electric heating element

② Apply to thermocouple protection tube:

Molybdenum disilicide based thermocouple protection tube has excellent characteristics such as high temperature resistance, corrosion resistance, good air tightness, heat shock resistance and long service life. The protective tube has been well used in the temperature measurement of high, medium and low pressure heavy oil gasifiers in China's chemical fertilizer industry. Because it replaces the expensive 99.95% alumina corundum tube imported from Japan, it saves a lot of foreign exchange for the country. In addition, the tungsten rhenium thermocouple, which is specially assembled with the tube and can be used for atmospheric temperature measurement, has also been well used in temperature measurement in metallurgy and other industries. Replacing precious metal thermocouple wire with cheap tungsten rhenium thermocouple wire is cheaper, so it saves the cost of temperature measurement for users. In addition to the exceptions shown above, molybdenum disilicide protective tube has also been widely used in temperature measurement of high-temperature and strong corrosion devices in petrochemical, coal chemical, carbon black, cement and machinery industries.

③ Apply to sensors:

In March 1986, the Department of materials science and engineering of the University of California successfully developed "molybdenum silicide thin film potential temperature sensor for turbine engine". It is reported that the molybdenum disilicide temperature sensor has a small volume and can be used for 1200 ℃ temperature measurement for a long time. Because the molybdenum disilicide layer in the sensor element is only 3-10 μ M thick, resulting in its resistivity (room temperature 350 μ Ω• (CM) is about 2 orders of magnitude greater than the theoretical value, and the resistance temperature coefficient is 11.95 × 10-3K。 The temperature sensor has the same function as the precious metal thick film resistance temperature sensor, and its outstanding feature is that the working upper limit temperature is twice as high as it.

Excerpt from ceramats

Technological innovation

Honesty is the foundation

Contact Number: +86-15698999555 |

Address: NO.6 ,SHENGHUA STREET,TAIHE DISTRICT, JINZHOU CITY, LIAONING PROVINCE, CHINA. |