Titanium carbide ceramics are typical transition metal carbides. Its bonding is made up of ionic, covalent and metallic bonds mixed in the same crystal structure, so TiC has many unique properties. The crystal structure determines the basic characteristics of TiC, such as high hardness, high melting point, wear resistance and electrical conductivity.

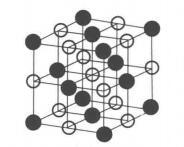

Crystal structure of titanium carbide

Titanium carbide is a transition metal carbide, and a NaCI type structure of face-centered cube is formed by inserting smaller C atoms into the octahedral position of Ti densely packed lattice, as shown in Crystal Structure of Titanium Carbide, and its space group is Fm3m. The real composition of titanium carbide is non-stoichiometric and is expressed by the general formula TiC.

There are three kinds of chemical bonds in this nacL-type structure: metallic bond, ionic bond and covalent bond. The metallic bond comes from the non-zero density of the Fermi energy state and the relatively high electron density in the region between the atomic spheres. Ionic bonding is the result of electrostatic force generated by the transfer of charge from Ti atom to C atom. Compared with the ideal crystal of neutral atoms, about 0.36 electrons migrate from the Ti atom sphere. The five 3D orbitals of a Ti atom split into three t2-symmetric and two Er-symmetric orbitals.

Characteristics

Titanium carbide TiC ceramics are face-core cubic crystal, high melting point, good thermal conductivity, hardness, chemical stability, no hydrolysis, high temperature oxidation resistance, at room temperature, not with acid reaction, but in nitric acid and hydrofluoric acid mixed acid can be dissolved, at 1000℃ in nitrogen gas atmosphere.

Preparation methods

Titanium carbide powder is generally prepared by the reaction of TiO2 and carbon black in the carbon tube furnace with hydrogen or in the vacuum furnace with frequency modulation at 1600℃--1800℃. Molding can use ceramic conventional molding method, burning generally using hot pressing method, can also use self-propagating high temperature synthesis method (SHS method), its advantages are energy saving, simple process, high purity of products.

Application

1. Multiphase materials: titanium carbide ceramics belong to super hard tool materials, TiC can be made with TiN, WC, Al2O3 and other raw materials into various multiphase ceramic materials, these materials have high melting point, high hardness, excellent chemical stability, is the preferred material for cutting tools, wear-resistant parts. Titanium carbide ceramics are used in the cutting of high speed wire regulating wheels and carbon steel because of their good oxidation resistance and no crescent - shaped wear with steel. Multiphase ceramic cutting tools containing titanium carbide have been widely used.

2. Coating material: As a surface coating, titanium carbide is a very wear-resistant material. In the diamond surface by physical or chemical method coated with some strong carbides to form metal or alloy, these metals or alloys at high temperature and diamond surface carbon atoms interface reaction, the formation of stable metal carbides. These carbides can not only bond well with diamond, but also be infiltrated by matrix metal, so as to enhance the adhesion between diamond and matrix metal. By depositing titanium carbide films on the tool, the tool life can be increased several times.

3. In the research of nuclear fusion reactor, titanium carbide coating material and (TiN+ TiC) composite coating material, after chemical heat treatment, generate tritium-resistant permeability layer on the surface of titanium carbide, can resist hydrogen ion irradiation and resist a large temperature gradient and thermal cycle.

4. In addition, titanium carbide can also make smelting tin, lead, cadmium, zinc and other metal crucible; Transparent titanium carbide ceramics are also good optical materials.

Technological innovation

Honesty is the foundation

Contact Number: +86-15698999555 |

Address: NO.6 ,SHENGHUA STREET,TAIHE DISTRICT, JINZHOU CITY, LIAONING PROVINCE, CHINA. |