With the development of modern industry, human civilization has achieved unprecedented prosperity. On the one hand, people enjoy the convenience brought by science and technology; on the other hand, they have to endure the environmental harm brought by industrial development. Especially all kinds of sewage and waste water discharge, not only aggravates the global water shortage, but also seriously threatens human health. In all kinds of sewage wastewater, dye wastewater has become one of the most difficult industrial wastewater treatment because of its complex composition, deep color, great harm and other characteristics.

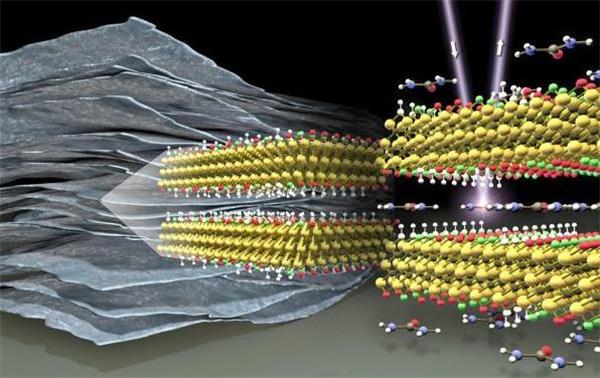

Figure 1 Image source network

The adsorption materials commonly used for dye wastewater treatment mainly include nano-metal oxides, biochar, metal-organic skeleton and graphene, but these adsorption materials have the disadvantages of single element, weak force, lack of functional groups on the surface and so on, and their adsorption performance is greatly limited. MXene as a dye adsorbent has the potential to overcome these shortcomings and has attracted much attention.

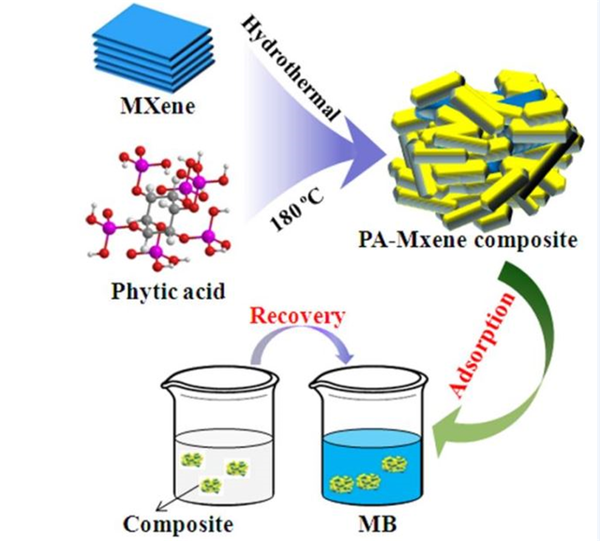

Figure 2 Image source network

The unique lamellar structure, high specific surface area, excellent surface hydrophilicity and abundant active sites of MXene enable it to be used as an adsorbent for dye molecules. Through theoretical and experimental research, the application of MXene in the field of dye wastewater treatment has made some progress.

At the same time, the large number of functional groups on the surface of MXene also makes it easier to combine with other functional materials to prepare composite materials, improving the treatment efficiency of dye wastewater. Cai[1] et al prepared ha-Mxene composite material by one-step hydrothermal method using phytic acid (HA) and Ti3C2(OHXF1-X)2 as the adsorbent of methylene blue and Rhodamine B. New functional nanostructures and compositions were generated by the reaction of HA and MXene to improve the adsorption capacity of MXene. The results showed that compared with MXene, the adsorption capacity of HA-Mxene for methylene blue and rhodamine B was greatly improved.

Figure 3 Source references

Although MXene and its composite materials have been widely studied in the field of dye wastewater treatment, in order to obtain better adsorption effect, the material itself and adsorption conditions need to be further improved.

(1) The key to improve the adsorption behavior of MXene is to study the appropriate dispersant or dispersion process to prevent the agglomeration of MXene during the adsorption process;

(2) Improving the stability and pollution resistance of MXene and composite materials in the adsorption process is an important direction to realize industrialization;

(3) Further study on modification of MXene to improve the adsorption performance of the material.

Guangzhou pressure on the yuan country graphene products quality supervision and inspection center (guangdong) equipped with X ray photoelectron spectrometer, laser microscopic confocal Raman spectrometer, X-ray diffractometer, ultraviolet visible near infrared spectrophotometer, ultra high performance liquid chromatograph, zeta potential, contact Angle meter and other high-end equipment, can be MXene membrane structure, The performance and the adsorption mechanism of dye molecules were detected and studied to help the development of MXene in the separation of antibiotics.

Figure 4. Uv-visible near-infrared spectrophotometer

Figure 5. Laser confocal Raman spectrometer

References:

[1] Cai C, Wang R, Liu S, et al. Synthesis of self-assembled phytic acid-MXene nanocomposites via a facile hydrothermal approach with elevated dye adsorption capacities[J]. Colloids and Surfaces A Physicochemical and Engineering Aspects, 2020, 589.

Source: Material Little Doctor

Technological innovation

Honesty is the foundation

Contact Number: +86-15698999555 |

Address: NO.6 ,SHENGHUA STREET,TAIHE DISTRICT, JINZHOU CITY, LIAONING PROVINCE, CHINA. |