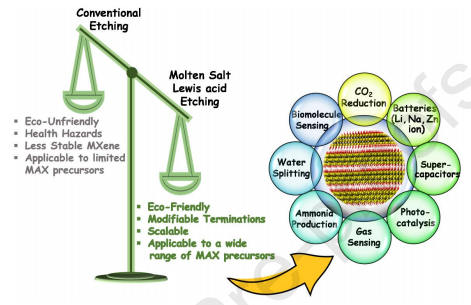

With the increasing demand for MXenes research, scientists are working hard to develop a greener

production pathway for MXenes. Molten salt Lewis acid etching is one of the important directions of

effort. This method has significantly addressed issues related to other methods, especially the use of

hf free reagents for synthesizing propylene. In addition, it implies the possibility of cutting surface

chemistry and enabling the surface to adopt rich and ideal functions. For example, substantial

electrochemical performance has been achieved by adjusting the surface portion. In this section, the

study delved into the method of synthesizing polybutadiene using Lewis acid etching and subsequent

modifications.

Fluorine-free MXenes are prone to acidic etching through molten salts: applications, challenges, and

future prospects

Fluoride free MXenes

Easy acid etching through molten salt

1. Systematically reviewed the synthesis mechanism of Lewis acid molten salts and pointed out that

they selectively corrode A-site elements through redox reactions.

2. It was emphasized that this method can obtain new MAX phases and new MXenes surface

functional groups such as Cl and Br.

3. Summarized the latest research progress in shortening synthesis time, open environment synthesis,

and in situ metal doping.The enhanced performance of MXenes obtained by this method in the fields

of electrochemical energy storage, sensing, etc. was summarized in detail.

4. Analyzed the current challenges faced by this method in improving yield and controlling oxidation.This is

the first comprehensive review specifically focused on the latest progress of this synthesis method.

5. It provides MXenes researchers with the latest developments and challenges in the development of

this method, which has important guiding significance.

6. It indicates that this method is a hot topic and development direction in current MXenes research,

demonstrating its broad application prospects.

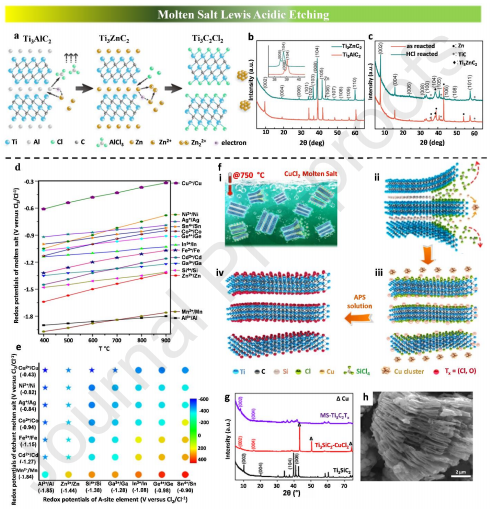

Figure 1 Schematic diagram of element substitution method and subsequent mechanism of Ti3C2Cl2 synthesis

Fig. 2 Schematic diagram of synthesis process of Ti3cncl2/RGO aerogel

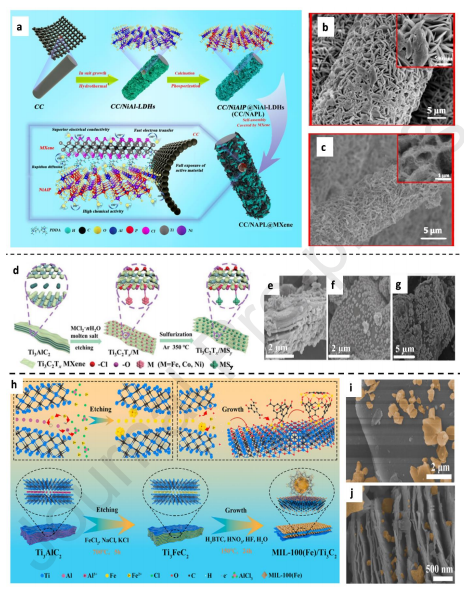

Figure 3 Schematic diagram of MXene synthesis and thiourea in-situ vulcanization of MX-Co

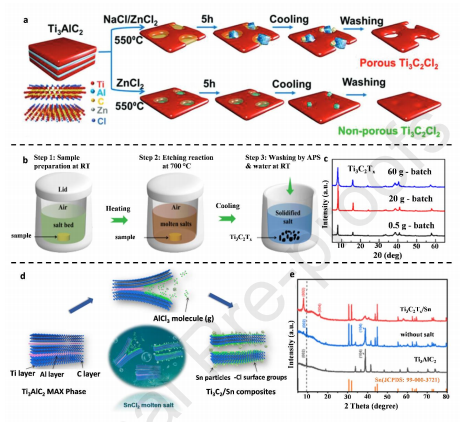

Figure 4 Schematic diagram of in plane porous Ti3C2Cl2 synthesized by MAX and salt mixture

Figure 5 Synthesis of CC through electrostatic attraction and self-assembly/ NAPL@MXene Schematic

diagram of the electrode

Latest progress in the synthesis of MXenes using Lewis acid molten salt corrosion method:

Lewis acid molten salt corrosion method is a groundbreaking new method, which is not only

environmentally friendly and efficient, but also allows for obtaining new MAX phases and controlling

MXenes surface chemistry. The mechanism of this method is Lewis acid oxidation of A-site elements,

halogen substitution, and matching MAX phase and Lewis acid based on redox potential. We have

successfully obtained new MAX phases based on Zn and Si, as well as MXenes with new surface

functional groups such as Cl and Br. Regulating reaction conditions can shorten synthesis time and

facilitate synthesis in an open environment. This method can obtain metal doped MXene in situ, and

further processing can obtain MXene heterojunctions.

The MXenes synthesized using this method exhibit excellent performance in electrochemical energy

storage, sensing, photovoltaics, electrocatalysis, and other aspects. However, this method still needs i

mprovement in terms of increasing yield, controlling oxidation, and obtaining more MAX and other aspects.

In summary, this method shows broad application prospects and is currently a hot topic and

development direction in MXenes research.

Technological innovation

Honesty is the foundation

Contact Number: +86-15698999555 |

Address: NO.6 ,SHENGHUA STREET,TAIHE DISTRICT, JINZHOU CITY, LIAONING PROVINCE, CHINA. |