Product Name: Zirconium Iron (ZrFe)

Specifications: 100 mesh, 200 mesh, 325 mesh

Appearance: Irregular

Color: Silver Grey

Features: Excellent wear resistance and strength

Usage: Deoxidizer and alloying agent in steelmaking industry, inoculant and spheroidizing agent in cast iron industry, reducing agent in ferroalloy production, etc

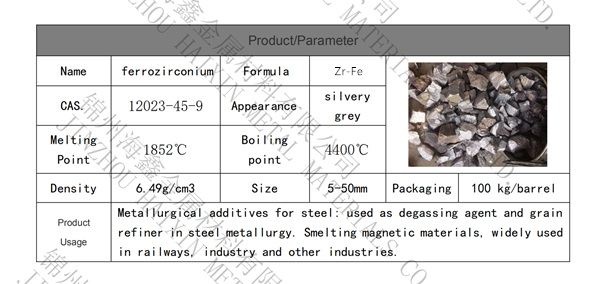

Name: Zirconium Iron

Molecular formula: FeZr

Cas:12023-45-9

Appearance: Silver gray

Melting point: 1852 ℃

Boiling point: 4400 ℃

Density: 6.49g/cm3

Particle size: 5-50mm

Packaging: 100kg/drum

Zirconium iron is an iron alloy composed of zirconium, iron, silicon, aluminum and other elements. The zirconium iron used in steelmaking is zirconium ferrosilicon, containing 15% to 45% Zr and 30% to 65% Si. The products produced by aluminum thermal method are called zirconium iron due to their aluminum content, with Zr content greater than 15%. Zirconium and iron form a stable compound FeZr2 (45.1% Zr) with a melting point of 1650 ℃. There are two co crystals in the Fe Zr system. At 16% Zr, the eutectic melting point is 1330 ℃; At 84% Zr, the eutectic melting point is approximately 940 ℃. Zirconium iron is used as a deoxidizer and alloy additive in high-temperature alloys, low-alloy high-strength steels, ultra high strength steels, and cast iron for special purposes, and is subsequently used in atomic technology, aviation manufacturing, radio technology, etc.

Technological innovation

Honesty is the foundation

Contact Number: +86-15698999555 |

Address: NO.6 ,SHENGHUA STREET,TAIHE DISTRICT, JINZHOU CITY, LIAONING PROVINCE, CHINA. |